Puning textile and garment industry started early, solid foundation, strong momentum, with the "clothing city" reputation, its printing and dyeing market is one of the important markets with a very large scale in Guangdong. This time, the ITCPE Guangzhou Textile Fair Organizing committee team came to Puning City, Guangdong Province, to visit the local well-known printing and dyeing industrial park. This large-scale modern printing and dyeing industrial park with a total investment of more than 3 billion yuan is the finishing touch to promote the transformation and upgrading of the printing and dyeing industry in Puning City.

Our main interview object is Puning Junlong Textile Printing and Dyeing Co., LTD. Puning Junlong Textile Printing and Dyeing Co., Ltd. since its establishment, with quality, innovation, environmental protection, service, focus as the business philosophy, to advocate the textile printing and dyeing revolution, the development of environmentally friendly textile varieties, the new company is located in Puning City South track development park, the main knitwear dyeing and finishing, printing and printing of high-grade fabrics, research and development.

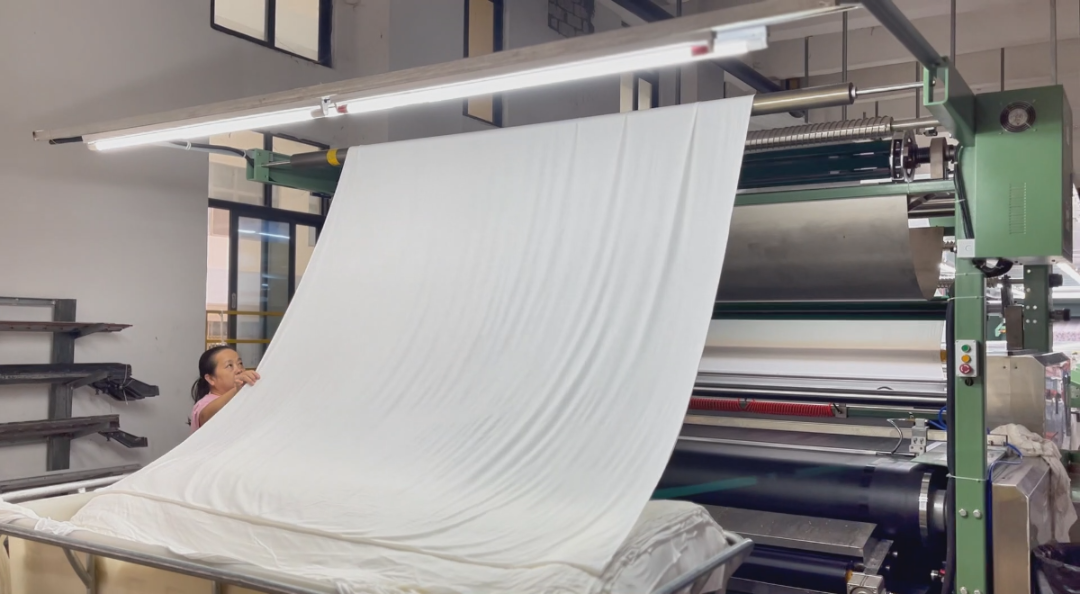

Once inside the factory building, the rumbling machine sound into the ear, through the factory door to look inside, I saw rows of tall neat machine equipment is running at high speed, workers in front of all kinds of equipment skillfully operated, colorful cloth continuously from the production line fast "flow" out.

"There are more than 180 people working in the whole plant, with an average daily output of 30-40 tons." Mr. Kong Zhenwei, general manager of Junlong Textile Printing and Dyeing Co., LTD., told us that the total annual production capacity of Junlong is about 18,000 tons and the annual output value is about 100 million yuan (RMB).

At present, Junlong Printing and dyeing factory is equipped with dyeing cylinder, setting machine, flat screen printing machine, rotary screen printing machine and a series of printing and dyeing equipment, complete technology, can provide customers with one-stop service.

Junlong has been focused on printing and dyeing processing industry for more than 30 years, from the beginning to the formation of large-scale production, with a stable source of customers, the key is that it has high-quality products and services. "I think the main lifeblood of a factory is quality, and a factory without quality cannot go far." Kong always told us that as long as we do a good job of a product, do fine, customers will continue to flow.

At the same time, Mr. Kong also revealed to us that Junlong's product positioning is biased towards the high-end, so in addition to the very high requirements when purchasing hardware equipment, it also has a strong design team for customers to do custom production, according to customer needs to provide different styles of patterns. "Whether it is children's wear, women's wear or men's wear, we can carry out the early development and design of the pattern and the later production of the product according to the positioning and needs of the customer, and the customer also relies on us."

"If you want to stay in the game, you have to innovate and design something that people can't do." For how to maintain their competitive advantage in the printing and dyeing industry, Mr. Kong replied.

It is understood that in addition to cotton knitting and chemical fiber product processing, Junlong has also increased the processing of other product categories. Mr. Kong told us that with the development of The Times, now only relying on a single product production can not meet everyone's needs, and rich product categories and changeable product design can win the favor of the market. "The variable product, fabric and process technology can break the previous production mode of single product solidification to a certain extent, which is conducive to process innovation and more demanding production to meet the challenges of the environment."

At present, the international relations continue to be tense, the cost of natural gas and other energy is high, especially the increase in the cost of water and electricity after entering the park, which brings great challenges to the completion of Long. General Kong said in this regard, "This requires us to learn to tighten costs, reduce losses, improve efficiency, such as improving one-time OK rate, product quality stability, reduce renovation rate and so on."

Asked about the current market environment, Mr. Kong said frankly that after several years of the epidemic, consumers' concepts tend to be rational, consumption is becoming more conservative, and the overall consumption power is not as good as before the epidemic, especially with the increase in labor costs and energy consumption costs, it is becoming more and more difficult to do business. Mr. Kong said that everyone is the same in the environment, what enterprises can do is to constantly improve themselves, enhance core competitiveness, and reduce costs while controlling product quality.

The market is changing, the demand is also changing, only to keep up with the changing needs of consumers, innovation and breakthrough enterprises can steadily move forward, let us look forward to the future development of Junlong!