The 9th ASEAN (Vietnam) International Textile, Clothing and Printing Industry Expo

Exhibition News

Vietnam International Textile, Clothing and Printing Industry Expo

Hangzhou IECHO Science & Technology Co., Ltd.

Booth No.: T008

See you at the expo: Aug 20-22!

Company Profile

Hangzhou IECHO Science & Technology Co., Ltd. is one of China's leading manufacturers and exporters of cutting equipment, with 30 years of experience, a 60,000-square-meter production workshop, and 30,000 cutting equipment installed in more than 100 countries. It provides comprehensive solutions for industries including signage, packaging, textiles, leather, furniture, automobiles, and composite materials.

In addition to the 60,000-square-meter new factory, parts warehouse, and QC system, there is also an independent product R&D and testing center and a production line for each product. The company has 6 production lines: PK&VK, BKL&BK2, BK3, BK4, TK4S, and GLSA&GLSC. With the launch of new products, the company plans to add more production lines, and each product has a corresponding production line.

IECHO has a complete service system and a professional after-sales service team, as well as professional pre-sales service teams, sales teams, technical teams, customer service agents, and export document specialists to provide you with professional services.

At the same time, the company has more than 100 R&D employees, including software department, hardware department, electrical department, and testing department. It collects customer feedback in a timely manner, upgrades products, and customizes products according to customer requirements.

Product Introduction

BKL

BKL is the product with the highest cost performance. It maximizes application scenarios within a limited budget.

BK2

Compared with the BKL model, the BK2 has an upgraded appearance, offering customers more choices.

BK3

The biggest difference between the BK3 and previous models is that it can install 3 heads at the same time, which allows it to meet more usage scenarios.

BK4

Compared with the BKL, the BK4 has an upgraded motor, enabling faster cutting and featuring an aluminum plate table.

TK4S

TK4S offers more machine size options to meet the needs of different users, with a wider cutting range.

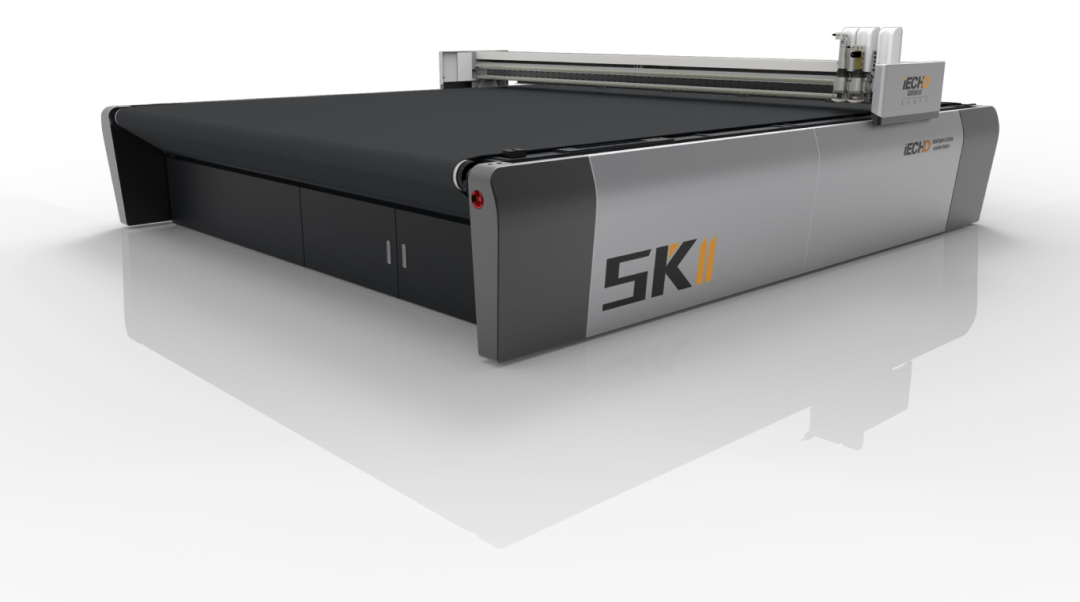

SK2

High-precision multi-industry flexible material cutting system, equipped with a magnetic scale. During operation, the machine head not only achieves more efficient processing efficiency but also improves cutting accuracy.

GLSA

The GLSA multi-layer cutting system provides the optimal solution for mass production of products in textiles, furniture, automotive interiors, luggage, medical care and other fields. Equipped with the IECHO high-speed electronic oscillating knife (EOT), it can cut soft materials with high speed, high precision and high intelligence.

GLSC

Compared with the GLSA, the GLSC has been upgraded in aspects such as the suction chamber, vacuum pump, floor space, maximum cutting speed, maximum cutting thickness, sharpening method, noise level, and intelligent tool position correction system. It can meet customers' higher requirements for precision and productivity.

LCKS1

The LCKS1 is equipped with a camera, special felt, a computer, and nesting software, enabling the entire process from spreading, scanning, nesting, cutting to material collection.

LCKX2

LCKX2 features a dual conveying platform with double crossbeams. It uses a reverse-position camera for aerial photography to identify leather contours and defects. The alternating cutting mode maximizes production efficiency.

In addition, activities such as online shopping and remote medical consultation are carried out to promote the modernization of rural areas.

LCKS3

The LCKS3 system consists of a three-section working platform, divided into the feeding area, scanning area, and cutting area. It features the capability to simultaneously perform spreading, contour scanning, zoning setup, nesting, and cutting. Leather materials are conveyed on the production line via felt, maximizing production efficiency.

PK0604/0705/1209

The complete PK product line can handle cutting various sizes of materials such as cardboard, paper, and self-adhesive, and supports fast cutting of paper sizes like A4 and B2.

PK1007

As an extension of the PK series, its cutting head can accommodate the cutting tools of the BK series, enabling more cutting operations.

VK

Simple horizontal and vertical cutting functions can be used for cutting advertising cloth, wallpaper, and banners. It is fast, easy to operate, and has a small footprint.

MCT

It can perform cutting, kiss-cutting and creasing at a high speed of 5,000 sheets per hour and is used for making gift boxes, business cards, labels, etc.

RK Digital Label Cutter

RK is a digital cutting machine for processing self-adhesive materials, applied in the post-printing field of advertising labels. This equipment integrates multiple functions including laminating, cutting, slitting, winding, and waste discharge. Combined with the roll guiding system, CCD positioning, and intelligent multi-cutting head control technology, it can realize efficient roll-to-roll cutting and automatic continuous processing.

LCT Laser Label Cutter

LCT350 is a high-performance digital laser processing platform. It is mainly used for full cutting, half cutting, fly-line cutting, punching, and waste removal of non-metallic materials such as self-adhesive, PP, PVC, cardboard, and coated paper. This platform does not require a die; instead, it adopts electronic file import for cutting, providing a better and faster solution for small orders and shortening the lead time.

-END-

- Exhibition Information

- Partners

- Contact Us

-

Guangzhou OfficeAdd: Room 1001-1010, Baoao Square ,No. 48 Hanxing Middle Road, Panyu, Guangzhou, GuangdongTel:020-83587112Ms.Tan:+86 18702018856

Mr.Zhuang:+86 19865189668

Mr.Tang:+86 18218678836

Ms.Tuo:+86 13640747074

Ms.Feng: +86 15802006188

Mr.Li:+86 13422198238

Ms.Mo:+86 13085718312 -

Shanghai OfficeTel:021-31007583Add: 6th floor CIMIC building, 800 Shangcheng Road, Pudong District, ShanghaiMr.Su: +86 13817048301

-

Vietnam OfficeTel: 020-83587112Add: VietnamMr.Nguyen: +84 90 132 1282

-

Hongkong OfficeTel: 00852-23181867Add: Room 7, 34 floor, 118 Connaught Rd West, Sheung Wan, Hong KongMr.Guo: 0085223181967