21st Guangzhou International Textile, Clothing and Printing Industry Expo

Exhibition News

The textile and clothing business in Puning has a strong history, solid roots, and bright futures. It's known as the "City of Garments," and one of Guangdong's biggest and most important markets is for printing and dying clothes. The team in charge of planning the ITCPE Guangzhou International Textile, Clothing, and Printing Industry Expo went to Puning City in Guangdong Province to check out the city's well-known printing and dying industrial park. With an investment of more than 3 billion yuan, this modern printing and dyeing industrial park is the last piece in Puning City's plan to change and improve the printing and dyeing industry.

Our main interviewee this time is Puning Junlong Textile Printing Co., Ltd. Since its establishment, Junlong Textile Printing Co., Ltd. has adhered to the business philosophy of quality, innovation, environmental protection, service, and focus. Advocating for a revolution in textile printing and dyeing, the company has developed eco-friendly textile varieties. The new company is located in the Nanning Development Park of Puning City, specializing in knitting fabric dyeing and finishing, processing and R&D of printed fabrics, and the printing, dyeing, and advanced finishing of high-grade fabric materials.

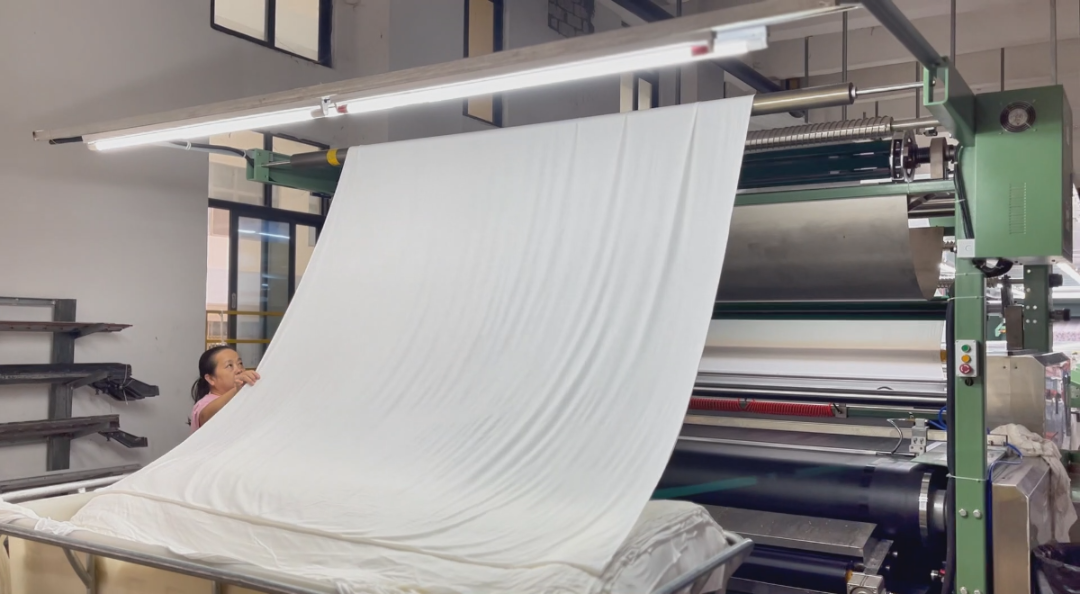

Upon entering Junlong's factory, the rumbling sound of machinery greets the ears. Looking through the factory gates, one can see rows of large and orderly machines operating at high speed. Workers skillfully operate various types of equipment, and colorful fabrics continuously and rapidly "flow" out from the production lines.

"The entire factory employs over 180 people in production and processing, operating two shifts day and night, with an average daily output of 30-40 tons," Mr. Kong Zhenwei, the General Manager of Junlong Textile Printing Co., Ltd., informed us. Junlong's annual total production capacity is approximately 18,000 tons, with an annual output value of around 1 billion yuan (RMB).

Currently, Junlong Textile Printing Co., Ltd. is equipped with a series of printing and dyeing equipment, including dyeing vats, setting machines, flat screen printing machines, rotary screen printing machines, and more, offering complete processes that enable the provision of one-stop services to customers.

Junlong has been in the printing and dyeing making business for more than 30 years, growing from a small start-up to the size it is now. Good goods and services are easy for it to get because it has a steady base of customers. "I think quality is what keeps a factory going." "In the long run, a factory that doesn't care about quality can't do well," Mr. Kong told us. Customers will keep coming back as long as the product is well-made and well-designed.

In addition, Mr. Kong said that Junlong's goods are aimed at the middle- to high-end market. In addition to having very strict rules about what technology to buy, the company also has a strong design team that can make custom products for customers by giving them different pattern styles based on their needs. "Whether it's children's wear, women's wear, or men's wear, we can carry out the initial pattern development design and subsequent product production based on the clients' positioning and needs, and our clients rely heavily on us," he stated.

"To avoid being eliminated, one must continuously innovate, designing something that others cannot achieve," Mr. Kong replied when asked about how to maintain a competitive edge in the printing and dyeing industry.

It is thought that Junlong can now process a wider range of goods than just cotton knits and synthetic fibre products. Regarding how things have changed over time, Mr. Kong told us that making just one product can't meet everyone's wants anymore. To do well in the market, you need a wide range of product types and designs that can be used in different ways. "Variability in products, fabric types, and process technologies can break away from the rigid production model of single-product cycles to a certain extent, which is conducive to innovation in craftsmanship and the pursuit of higher production standards, so as to meet the challenges of the broader environment," he stated.

With ongoing international tensions and high costs of natural gas and other forms of energy, especially the increased costs of water, electricity, and gas after moving into the industrial park, Junlong faces significant challenges. To this, Mr. Kong stated, "This requires us to learn to tighten costs, reduce losses, and improve benefits. For example, improving the first-time OK rate, the stability of product quality, and reducing the rate of rework, and so on."

When asked about the current state of the market, Mr. Kong was honest and said that after several years of the pandemic, buyers have become smarter and less likely to spend. Overall consumption has not returned to pre-pandemic levels. This is particularly true now that the costs of labour and energy are going up, making it harder and harder to run a business. This may become the norm. Mr. Kong said that all businesses face the same problems because of the way the market is right now. A business can keep getting better, become more competitive in its key areas, and keep costs down while maintaining product quality.

The market is changing, and so are the demands. Only those enterprises that keep up with the ever-changing needs of consumers and engage in innovation and breakthroughs can move forward steadily. Let's all look forward to the future development of Junlong!

- Exhibition Information

- Partners

- Contact Us

-

Guangzhou OfficeAdd: Room 1001-1010, Baoao Square ,No. 48 Hanxing Middle Road, Panyu, Guangzhou, GuangdongTel:020-83587112Ms.Tan:+86 18702018856

Mr.Zhuang:+86 19865189668

Mr.Tang:+86 18218678836

Ms.Tuo:+86 13640747074

Ms.Feng: +86 15802006188

Mr.Li:+86 13422198238

Ms.Mo:+86 13085718312 -

Shanghai OfficeTel:021-31007583Add: 6th floor CIMIC building, 800 Shangcheng Road, Pudong District, ShanghaiMr.Su: +86 13817048301

-

Vietnam OfficeTel: 020-83587112Add: VietnamMr.Nguyen: +84 90 132 1282

-

Hongkong OfficeTel: 00852-23181867Add: Room 7, 34 floor, 118 Connaught Rd West, Sheung Wan, Hong KongMr.Guo: 0085223181967