21st Guangzhou International Textile, Clothing and Printing Industry Expo

Exhibition News

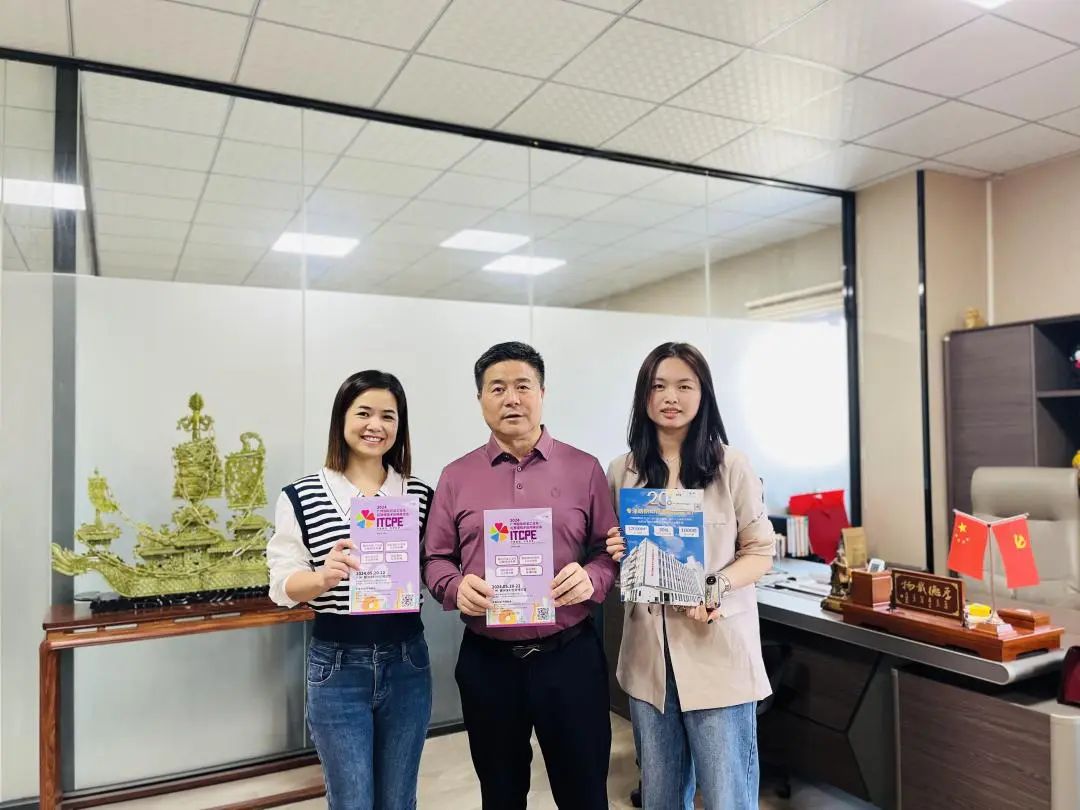

Recently, the ITCPE TEAM paid a visit to Foshan Xinmingxiang Textile Technology Co., Ltd. for information exchange.

Once we came to Xinmingxiang, Lin Minggui, the CEO coordially welcomed us. He led us to visit his factory. Through his introduction, we learned that Xinmingxiang has a series of equipment, including Chuanghui Flatbed Printer, Huisheng Rotatry Printing Machine, Yongxin Continous Fabric Streamer, Shaoyang Sizing Machine, Fuda Washing Machine, Xinyuan Pre-shrinking Machine, Jinchang Flat/Round Mesh Automatic Drying Machine and a series of finishing equiment, catering the requirement of high-quality mass production.

Foshun Xinmingxiang Textile Technology Co., Ltd. was founded in June 2020. It is a new factory specializing in the printing of knitted and woven garment fabrics. The company is located at No. 288 Hefu Road, Hecheng Street, Gaoming District, Foshan City, Guangdong Province. The total investment is over 30 million yuan, and the land area is 12,000 square meters. The business scope includes:

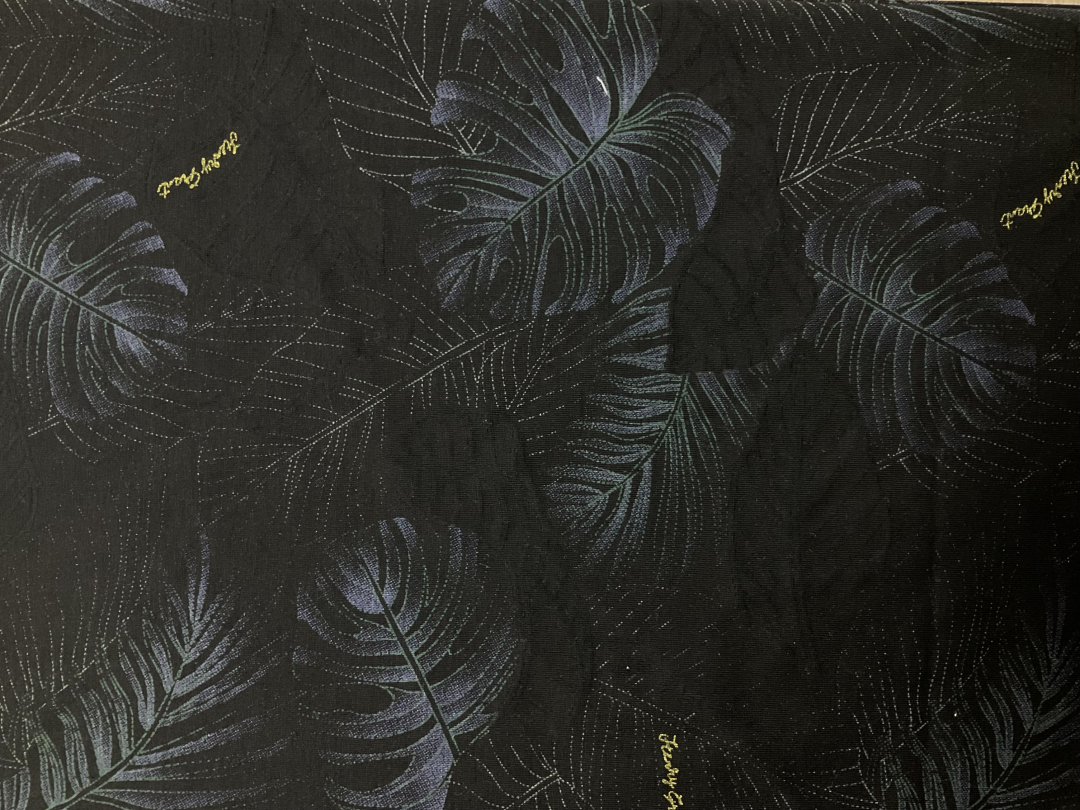

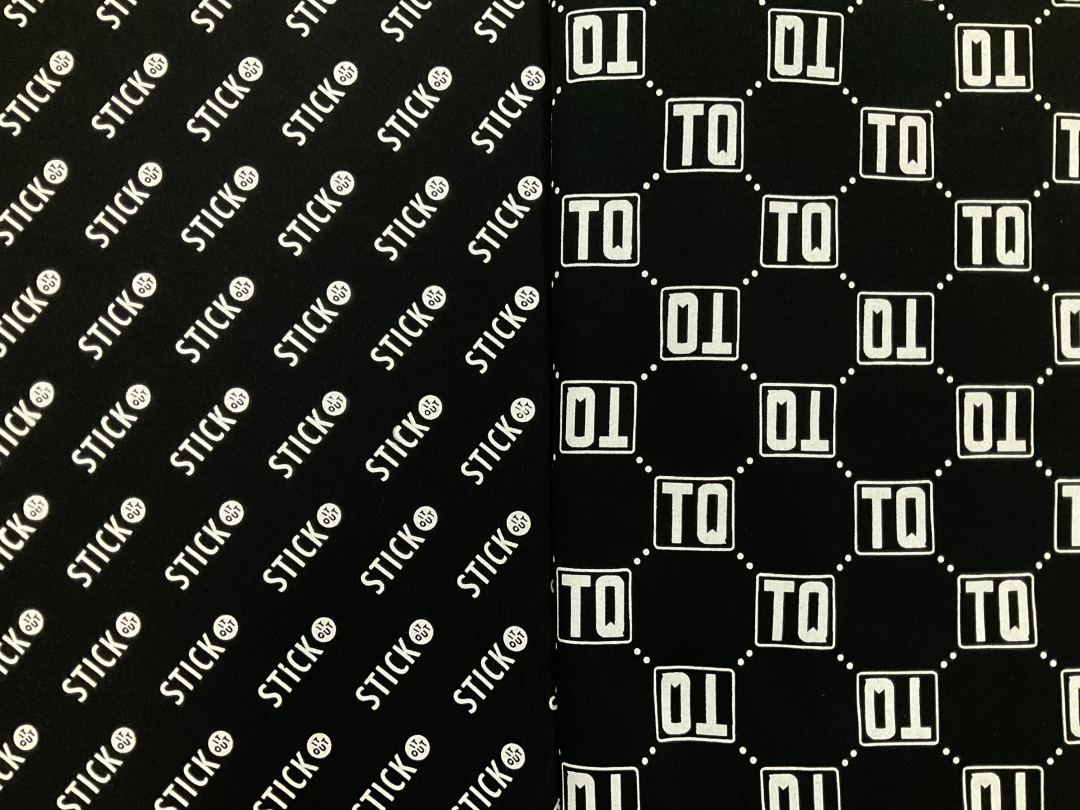

Digital printing, flat-bed and rotary screen printing (including reactive printing, simulated reactive printing, pull printing, single-guide printing, three-proof printing, and glue printing) technology;

Pretreatment (burning hair, cold pile, washing, semi-bleaching) and finishing (grinding, brushing, grabbing, cutting, sizing, pre-shrinking, etc.).

Recently, Xinmingxiang Textile added a new 7A Smart Antibacterial Space Capsule. After 150 washes, the 7A antibacterial fabric can still effectively inhibit the growth of Staphylococcus aureus, Escherichia coli, Candida albicans, and Gardnerella vaginalis. It can also effectively inhibit the growth of bacteria for a long time, prevent the generation of odor, reduce the risk of bacterial infection and transmission, and achieve anti-mite and mosquito repellent effects.

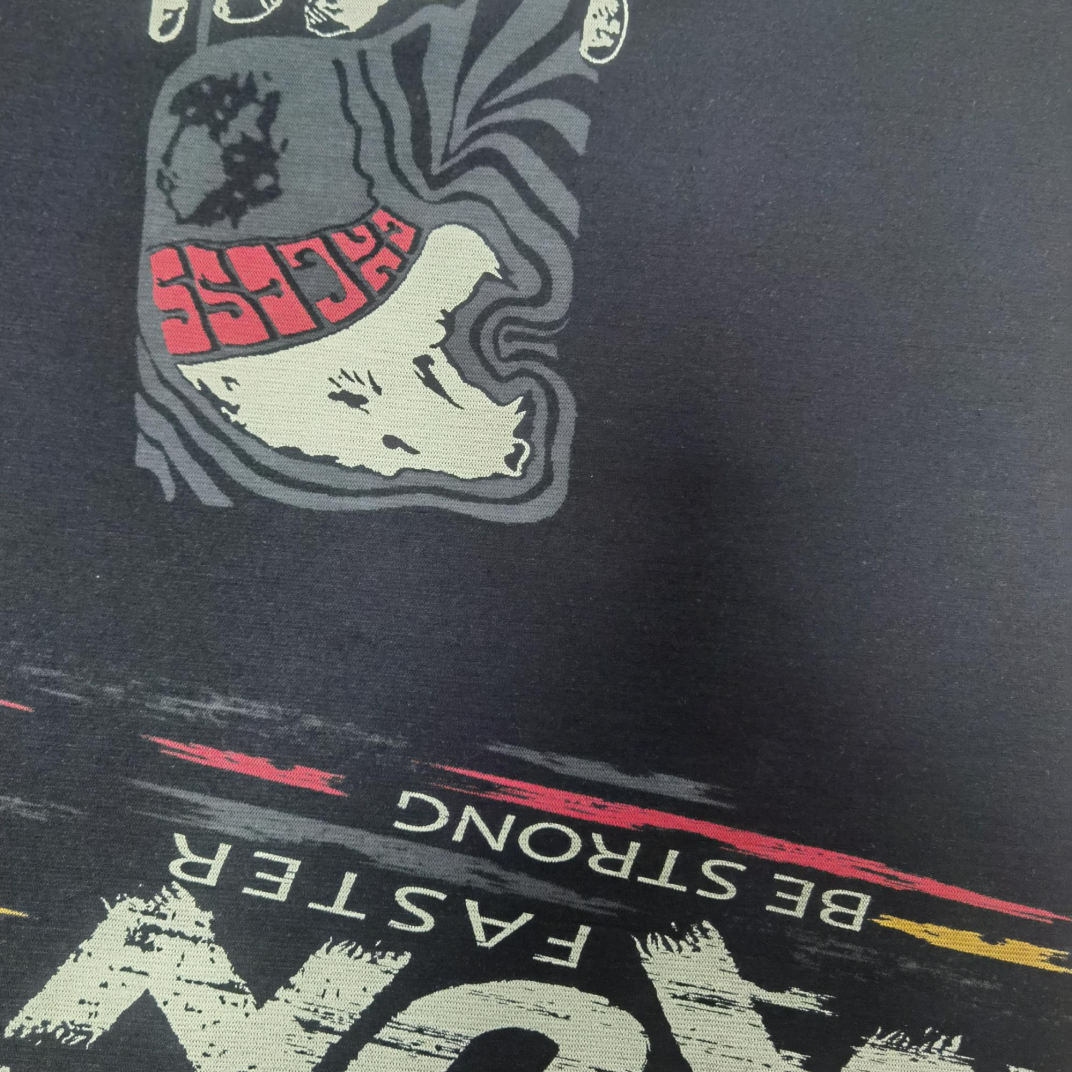

Processes Showcase

Discharge Printing

Powder

Paste

Reactive

Foaming Processing

The factory has five floors, covering the processes from pre-treatment, such as washing, semi-bleaching, sizing, cold pad batch dyeing method, sanding, fleece raising, crocheting, and brushing, to flat-bed printing, rotary printing, and digital printing. It can achieve one-stop production.

Mr. Ling said that Xinmingxiang mainly produces Class A products for infants and toddlers. These products are strictly manufactured in accordance with the GB 31701-2015 standard, which has strengthened three safety indicators. The safety requirements have been comprehensively upgraded from the original GB 18401 standard. In addition, Xinmingxiang has established good cooperative relationships with well-known brands such as Annily, Balabala, Goodbaby, Anta Children, Children King, and Li Ning.

“Because we only produce Class A products, the requirements for product quality are relatively strict and the threshold is high. We can only stand out in the fierce market competition by doing things that others cannot do.”

Xinmingxiang's OEKO-TEX100 Certificate

Samples

When we aksed about the landscape of the whole market this year, Mr Lin said that the recovery needs time although the COVID has passed away. Currently, we have day shift and night shift. Although our factory is not working at full capacity, we are rushing to ship goods every day. Basically, we process the customer's materials as soon as they arrive and then ship them out."

Driven by the "fast fashion" trend and its emphasis on "Small Profit, Quick Returns," on-demand production and responsiveness have become crucial industry priorities. This shift makes digital textile printing increasingly attractive due to its flexibility. However, traditional printing still dominates bulk production due to cost advantages. General Manager Lin acknowledges the cost concerns surrounding digital printing, but highlights promising new technologies that integrate online sizing, direct-to-garment printing, and rotary screen printing. These innovations aim to reduce costs and cater to varying production demands, potentially making digital printing the mainstream solution once fully matured.

Tie-dye Effect

Meanwhile, Mr. Ling revealed Xinmingxiang's plans to purchase more anti-bacterial equipment to expand their capabilities to handle products with mite-resistant fabrics. He views ITCPE 2024 as an effective platform to explore the latest technologies and high-quality machinery. Mr. Ling expressed his strong interest in attending ITCPE and hopes to discover a bounty of innovative and advanced equipment at the exhibition.

- Exhibition Information

- Partners

- Contact Us

-

Guangzhou OfficeAdd: Room 1001-1010, Baoao Square ,No. 48 Hanxing Middle Road, Panyu, Guangzhou, GuangdongTel:020-83587112Ms.Tan:+86 18702018856

Mr.Zhuang:+86 19865189668

Mr.Tang:+86 18218678836

Ms.Tuo:+86 13640747074

Ms.Feng: +86 15802006188

Mr.Li:+86 13422198238

Ms.Mo:+86 13085718312 -

Shanghai OfficeTel:021-31007583Add: 6th floor CIMIC building, 800 Shangcheng Road, Pudong District, ShanghaiMr.Su: +86 13817048301

-

Vietnam OfficeTel: 020-83587112Add: VietnamMr.Nguyen: +84 90 132 1282

-

Hongkong OfficeTel: 00852-23181867Add: Room 7, 34 floor, 118 Connaught Rd West, Sheung Wan, Hong KongMr.Guo: 0085223181967