21st Guangzhou International Textile, Clothing and Printing Industry Expo

Exhibition News

In recent years, with the continuous advancement of technology and the increasing diversification of consumer demands, the sewing industry is undergoing unprecedented changes. From the popularization of intelligent sewing machines to the widespread application of automated equipment, and then to the deep integration of AI technology, the sewing industry is moving towards the future with a brand-new attitude. Recently, the media team of Allallinfo interviewed a number of sewing equipment enterprises to jointly explore the current development dynamics and future trends of the sewing industry.

01 Intelligent Sewing Machines: Technological Innovation Enhances Efficiency and Quality

As a core piece of equipment in the sewing industry, the technological innovation of intelligent sewing machines is directly related to the production efficiency and product quality of the entire industry. In recent years, major sewing equipment enterprises have launched intelligent sewing machines with independent intellectual property rights. By integrating advanced AI technology, sensor technology and control algorithms, they have realized the intelligence and automation of the sewing process.

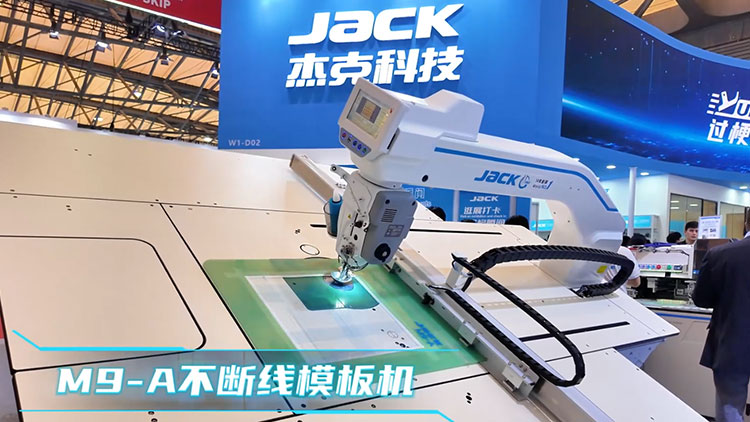

Taking Jieke's Quick Response King II as an example, this product is equipped with the "Nine-Brain Octopus" dual-core AI chip and the "Daliyuan" dual-engine motor. It not only features an oil-free design during high-speed operation but also improves the motor's anti-static interference capability through magnetic encoding technology, ensuring stability during long-term operation. Meanwhile, its M9-A non-thread-breaking template machine further integrates the 0° Thread Path 2.0 technology and 0-Second Synchronization 2.0 technology, enabling automatic bobbin change and unmanned operation, which significantly enhances production efficiency.

The H9V3 lockstitch machine launched by HIKARI is also eye-catching. Based on the original intelligent thread tension control technology, this machine has added four quantity trajectory modes and a better oil control method. It features a thread end of only 2 millimeters and an intelligently adjustable presser foot, making it a relatively high-end lockstitch machine in the industry. In addition, HIKARI has also launched an automatic open hem workstation, which realizes fully intelligent grabbing, identification, sewing and material collection. One person can operate 20 machines, greatly improving production efficiency.

02 Automated Equipment: Cost Reduction and Efficiency Enhancement Become the Industry Mainstream

With the rise in labor costs and increasing consumer demands for product quality, automated equipment is being used more widely in the sewing industry. From pocket opening machines and pocket attaching machines to template machines and loading/unloading robots, automated equipment is gradually replacing traditional manual operations and becoming the mainstream in the industry.

Zhongjie's Thread Trace Master, automated pocket opening machines, and pocket attaching machines are typical examples. Zhongjie's Thread Trace Master ensures straight thread traces and stable quality through bird's nest-free bobbin thread detection technology and a design that maintains consistent stitch length even for thick materials. Meanwhile, the automated pocket opening and attaching machines, equipped with rotating machine heads and visual recognition functions, achieve automatic pattern recognition for both thin and thick materials and precise sewing, significantly improving production efficiency and product quality.

03 AI Technology: Deep Integration Usher in a New Era of Sewing

The deep integration of AI technology is ushering in a new era for the sewing industry. From AI visual analysis systems to AI-enabled sewing machines, AI technology is gradually transforming the production methods and business models of the sewing industry.

The first AI sewing machine, Ai 10 Lockstitch Machine, launched by Aitu Company, is a model of AI technology application in the sewing industry. This machine integrates an AI visual analysis system and a 7-inch touchscreen operation interface, which can help operators quickly identify bottlenecks in movements and productivity, improve sewing skills, and enhance the production line balance rate. Meanwhile, by real-time capturing of employees' hand gestures via cameras and recording of working hours, the AI visual analysis system can also conduct comprehensive comparisons. This helps employees find directions for improvement and encourages them to learn from role models.

04 Multi-Layer Cutting Technology: Dual Improvement in Efficiency and Precision

In the cutting process, the application of multi-layer cutting technology is becoming an industry trend. The Version 2.0 multi-layer "cut-while-moving" cutting equipment launched by Hangzhou Aike Technology Co., Ltd. has achieved significant improvements in cutting speed, efficiency, and precision. By adopting the cut-while-moving technology, this equipment increases cutting efficiency by approximately 50% while ensuring cutting precision and quality. The application of this technology not only improves production efficiency but also reduces material waste during the cutting process, bringing significant economic benefits to enterprises.

Looking ahead, the sewing industry will continue to maintain a trend of rapid development. With the continuous advancement of technology and changing consumer demands, sewing equipment enterprises need to innovate constantly and launch more high-quality products that meet market needs. At the same time, enterprises also need to strengthen cooperation with upstream and downstream industries to jointly promote the transformation, upgrading and high-quality development of the sewing industry.

The sewing industry is undergoing an unprecedented transformation. The application of intelligent sewing machines, automated equipment, AI technology, and multi-layer cutting technology is driving the industry toward greater efficiency, smarter operations, and enhanced environmental friendliness. From May 19 to 21, 2026, the 21st Guangzhou International Textile, Clothing and Printing Industry Expo (referred to as "ITCPE Guangzhou Textile Expo") will kick off at the Poly World Trade Center Expo in Pazhou, Guangzhou. This expo will bring together more cutting-edge industry technologies and innovative achievements. Let us jointly look forward to this industry grand event and witness a more brilliant future for the sewing industry!

-END-

- Exhibition Information

- Partners

- Contact Us

-

Guangzhou OfficeAdd: Room 1001-1010, Baoao Square ,No. 48 Hanxing Middle Road, Panyu, Guangzhou, GuangdongTel:020-83587112Ms.Tan:+86 18702018856

Mr.Zhuang:+86 19865189668

Mr.Tang:+86 18218678836

Ms.Tuo:+86 13640747074

Ms.Feng: +86 15802006188

Mr.Li:+86 13422198238

Ms.Mo:+86 13085718312 -

Shanghai OfficeTel:021-31007583Add: 6th floor CIMIC building, 800 Shangcheng Road, Pudong District, ShanghaiMr.Su: +86 13817048301

-

Vietnam OfficeTel: 020-83587112Add: VietnamMr.Nguyen: +84 90 132 1282

-

Hongkong OfficeTel: 00852-23181867Add: Room 7, 34 floor, 118 Connaught Rd West, Sheung Wan, Hong KongMr.Guo: 0085223181967